Business Overview

- Sight Machine, a leading AI-based company in the digital manufacturing space, faced resource constraints during their product development.

- They sought expertise in generative AI and ML models to augment their product capabilities, leading them to collaborate with SoluLab.

- SoluLab contributed to Sight Machine’s tech product development, leveraging cutting-edge technologies to enhance their digital twins offerings.

The Challenges

- Sight Machine encountered resource limitations, hindering their ability to deliver advanced solutions in the digital twins domain.

- They sought a reliable technology partner capable of providing generative AI and ML models expertise to augment their product capabilities.

- The need to develop a scalable technical architecture, integrate generative AI models, and derive meaningful insights from data posed challenges for the project.

Solutions

-

Technical Architecture Design

SoluLab devised a scalable and efficient technical architecture tailored to Sight Machine's requirements.

-

Generative AI Model Integration

SoluLab incorporated state-of-the-art generative AI models, such as GANs, VAEs, and CNNs, into Sight Machine's digital twins platform.

-

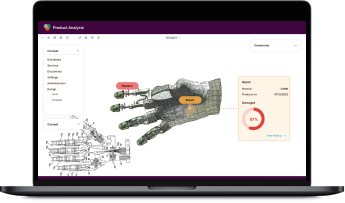

Data Integration and Analytics

SoluLab integrated Sight Machine's data sources into a unified management system and developed advanced analytics capabilities.

-

Customization and User Experience

SoluLab focused on enhancing the user experience by developing intuitive interfaces and interactive dashboards.

-

Scalability and Performance Optimization

SoluLab ensured the platform's scalability and performance through efficient algorithms and data processing techniques.

-

Collaboration and Knowledge Sharing

SoluLab implemented collaboration and knowledge-sharing capabilities to foster cross-functional collaboration and holistic asset management.

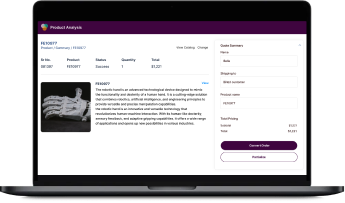

Project Features

- Scalable and efficient technical architecture design.

- Integration of state-of-the-art generative AI models.

- Unified data management system with advanced analytics capabilities.

- Customizable interfaces and interactive dashboards.

- Scalability and performance optimization through efficient algorithms.

- Collaboration and knowledge-sharing capabilities for holistic asset management.

Outcome

- Sight Machine’s digital twins platform enhanced with accurate virtual representations and real-time data integration.

- Improved manufacturing process monitoring, analysis, and optimization.

- Data-driven decision-making and proactive maintenance.

- Enhanced operational efficiency, reduced downtime, and improved productivity.